Our Carbon Footprint

Our Goal: To Be the Most Eco-Friendly Custom Credit Card Producer in the United States

Perfect Plastic Printing has recently completed an expansion that doubled our square footage and our capacity for custom credit cards. We saw this as a tremendous opportunity to renew our commitment to the environment and produce a facility with a goal to achieve an exceptional reduction in CARBON EMISSIONS for card manufacturing!

How did we do?

Championing Carbon Neutrality: We’re setting a science-based target to achieve net-zero emissions in the future. As a significant step towards this goal, we’ve achieved carbon neutrality across our entire operation. This means every custom credit card produced at Perfect Plastic Printing has a minimized impact on greenhouse gas emissions. Here’s how we’re achieving this:

- Efficiency Revolution: We’ve meticulously analyzed and optimized our production processes, resulting in significant energy reductions. Our new building expansion, for example, boasts a 55.7% decrease in electricity usage compared to industry standards.

- Solar Powerhouse: We harness the power of the sun, generating clean energy through a vast solar panel array that produces enough electricity to power hundreds of homes annually. This not only reduces our reliance on fossil fuels but also displaces a substantial amount of carbon dioxide emissions.

- Offsetting Our Footprint: For unavoidable emissions, we invest in high-quality carbon offset programs, ensuring a responsible production process.

- Waste Reduction Warriors: Minimizing waste is a core tenet of our sustainability philosophy. We achieve this through:

- Rigorous Recycling: A staggering 92% of our waste is diverted from landfills through a comprehensive recycling program. We even offer a convenient card return and recycling program for your customers’ used cards, ensuring responsible end-of-life management.

- Sustainable Products: We currently offer 100% recycled PVC cards in both white and black core. Our goal is to produce all cards on recycled PVC by Q3 2025. We’re also researching alternative materials like PETG, PLA, Biodegradable options, and Wood to further reduce our environmental impact.

- Smart Material Selection: We continuously explore and implement the use of recycled and alternative materials in our card production. This reduces our reliance on virgin resources and minimizes our environmental impact.

Sustainable Production from Start to Finish: Our commitment to sustainability extends beyond just materials and energy. Here are some additional highlights:

- Clean Chemistry: We’ve eliminated Volatile Organic Compounds (VOCs) from our printing process by utilizing 100% UV-curable inks, safeguarding both worker health and the environment.

- Smart Lighting: Our entire facility, from production floors to offices, utilizes motion-sensor LED lighting, significantly reducing energy consumption without compromising productivity.

- Electric Vehicle (EV) Friendly: We’ve installed six EV charging stations on-site, encouraging the adoption of clean transportation for both employees and visitors.

Your Competitive Advantage: Partnering for a Sustainable Future

By choosing Perfect Plastic Printing as your custom credit card manufacturer, you gain a significant edge:

- Enhanced Environmental Credentials: Partnering with a leader in sustainable manufacturing strengthens your own environmental commitment and allows you to effectively communicate your sustainability goals to your customers.

- Potential for Reduced Carbon Footprint: Credit cards produced in our facility can help you achieve your own carbon footprint reduction goals. While we are still gathering comprehensive data on the lifecycle impact of our cards, our focus on sustainable practices positions us well to minimize environmental impact.

- Attract Environmentally Conscious Customers: Today’s consumers are increasingly conscious of the environmental impact of the products they use. Partnering with Perfect Plastic Printing allows you to showcase your commitment to sustainability, attracting environmentally conscious customers who value responsible business practices.

Building a Greener Future Together

Sustainability is a journey, not a destination. At Perfect Plastic Printing, we’re constantly innovating and exploring new ways to minimize our environmental impact. We believe in fostering a collaborative approach to sustainability and are dedicated to supporting your environmental initiatives. We’re here to be your trusted partner, helping you achieve your sustainability goals and build a greener future for the banking industry.

Recycling

- Scrap Plastic Shredding & Recycling: All plastic scrap generated in custom credit card production, such as plastic skeletons from cut sheets and shredded card waste, are turned over to a plastic recycling firm. Local recycling facilities transform them into stock used to manufacture other plastic products such as composite decking & spacers.

- Recycled Packaging Materials: We receive our raw materials packaged in paper, cardboard, and plastic. These materials are separated, collected, and turned over to recycling firms.

- Scrap Metal Recycling: Credit card production generates scrap aluminum print plates, scrap stainless steel lamination plates, and steel stamping dies. When these have reached the end of use, they are turned over to a metal recycling firm.

Facilities Energy Savings Initiatives

Energy intensive equipment are routinely serviced to improve energy efficiency and reliability. We are systematically replacing electrical devices in the plant with more energy-efficient versions. We have upgraded the illumination system thourghout the production facility with motion sensing, high-efficiency LED technology. Lights are on only in occupied areas and are up to 40% more efficient while illuminating our production floor. High efficiency LED lighting is scheduled for installation for our executive office facility Q4 2024.

Carbon Offsets for Natural Gas

In fourth quarter of 2021, Perfect Plastic Printing signed an agreement for carbon offsets of natural gas. The agreement will offset 100% of natural gas consumed by Perfect Plastic. In 2022, we offset 359 metric tons of CO2. These efforts contribute to our goal of reaching Carbon Neutral Emissions for Card Manufacturing.

- Carbon Footprint reduction / elimination

- CO2e: Scope 1 – 366.1 Metric Tons

- Carbon offsets cover 359.2 Metric Tons

- Balance CO2e = 6.9 Metric Tons

- CO2e: Scope 2 – 2003.5 Metric Tons

- CO2e: Scope 1 – 366.1 Metric Tons

- Learn More About our Responsible Card Production.

- To learn more about how you can reduce your carbon footprint at home or at work, visit the EPA website.

Here are some of the highlights from our renovation:

Solar Panels

In addition to the SolarWall System, our new addition features a roof installed 814 KW solar panel array. The Solar Panel Array, installed in 2021; will generate up to 1,000,000 KWh of electricity annually; enough energy to power 1200 homes. Unlike traditional fossil fuels used for electricity, solar panels don’t produce emissions while generating power. That’s why solar energy is important to slash CO2 emissions and slow climate change.

- 2022 Production: 929,409 kWh

- CO2 Emissions avoided: 1,452,846 lbs

- On Average our personalization department is running on 100% Solar Power 17.2% of each day

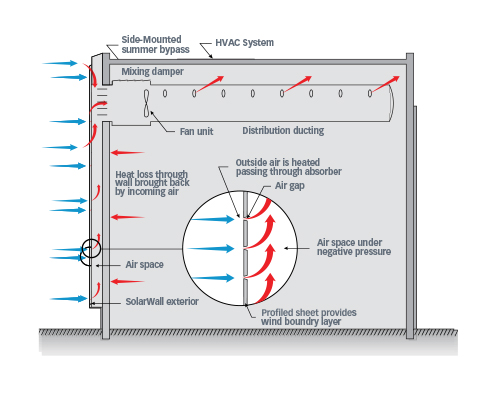

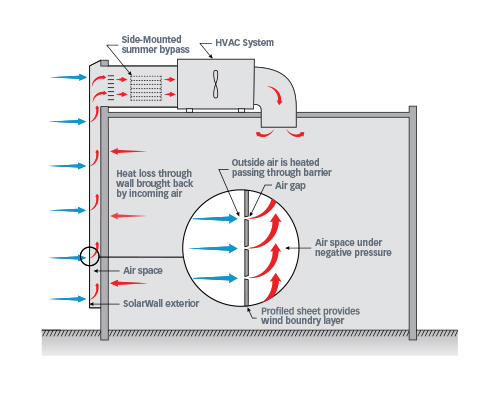

Solar Wall

We are extremely proud to share that our expansion incorporates solar air heating with SolarWall. Independent monitoring data indicates that SolarWall systems displace between 20-50% of heating fuel consumption.

SolarWall systems produce up to 60 watts/ft2 (600 watts/m2) of thermal energy (1.5-3.5 therms/ft2 or 1.5-3.5 GJ/m2 per year). When the sun warms the surface of the collector, the heated air is drawn through thousands of tiny perforations on the surface and ducted to the existing air intake. On a sunny day this air will be heated anywhere from 30-70˚F (16-38˚C) above ambient. The solar heated air is then distributed throughout the building via the conventional ventilation system or dedicated fans and ducting. The SolarWall technology heats fresh air, so it also improves indoor air quality.

We Encourage the Use of Electric Vehicles

To reduce the impact of vehicle pollution and oil consumption, six electric car charging stations are available at Perfect Plastic.

- Learn More about Our Responsible Card Production